Surveying

Learn More

Photogrammetry

Learn More

LiDAR Services

Learn More

GIS / CAD

Learn More

Digital Twins

Learn More

BIM

Learn More

Geospatial technology presents smarter solutions for a rapidly changing world

Geospatial technology is transforming the economies and societies in the digital era. We assist organizations around the world in advancing their objectives in a rapidly changing world with reliable, fast, and high-quality geospatial information through our services, custom solutions and products

Range of mapping, imagery and security solutions for quick, Reliable, actionable data

Our Product Partners

Reliable and consistent survey grade data

SAR satellite-based one-stop solutions

Industries We Serve

Custom solutions for sectors that matter the most

Our Experience

0Million

Imageries processed for

Aerial triangulation

Aerial triangulation

0Million Sq.km

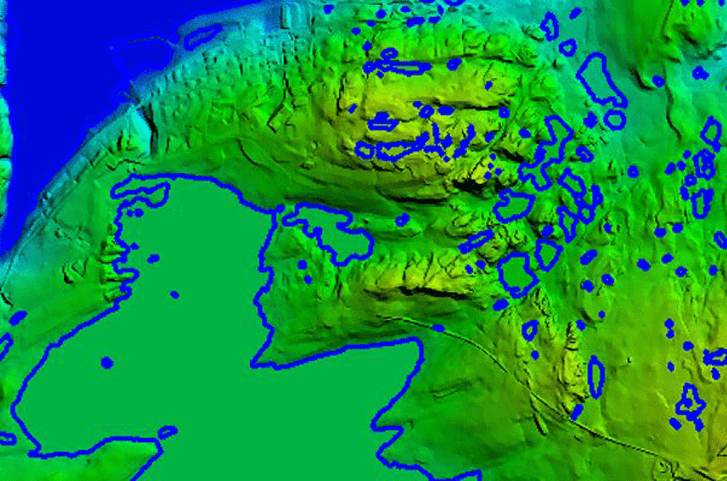

Ortho Photo Production

0Million Sq.km

DTM collection

0Sq.km

Airborne LiDAR data processing

0Sq.km

Feature Extraction

0Sq.km

GIS data conversion